OUR TECHNOLOGY

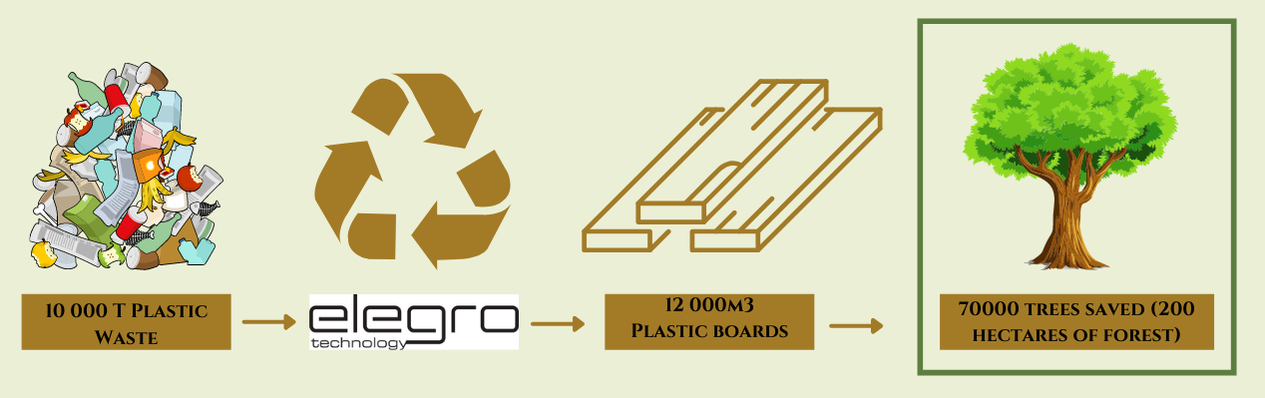

We have created a unique technology and, as a result, we are able to change the world with it. Elegro technology focuses on recycling mixed plastic generated by households.

Traditionally in plastics recycling, added value is created in sorting and processing plastic waste into plastic streams, identified by the plastic type. This includes separating different types of plastics (e.g. polyethylene and polypropylene).

In case of Elegro Technology, specific sorting of plastic is not needed and collected mixed plastic can be used for further processing.

With patented Elegro Technology, plastic waste gets a new life and can be reused repeatedly. Elegro Technology does not use water during the process, therefore, the technology is waste-free – all input materials are reused. Moreover, the value of the material increases during the recycling process and products get an exclusive look. Primary material can be covered by weatherproof decors by using special heat treatments processes. As a result, Elegro Technology can provide a product that is beautiful and resistant to weather conditions.

Traditionally in plastics recycling, added value is created in sorting and processing plastic waste into plastic streams, identified by the plastic type. This includes separating different types of plastics (e.g. polyethylene and polypropylene).

In case of Elegro Technology, specific sorting of plastic is not needed and collected mixed plastic can be used for further processing.

With patented Elegro Technology, plastic waste gets a new life and can be reused repeatedly. Elegro Technology does not use water during the process, therefore, the technology is waste-free – all input materials are reused. Moreover, the value of the material increases during the recycling process and products get an exclusive look. Primary material can be covered by weatherproof decors by using special heat treatments processes. As a result, Elegro Technology can provide a product that is beautiful and resistant to weather conditions.